History

Mayekawa Manufacturing Company has expanded its business by focusing on freezing and compression technologies since its founding in 1924. As a heating engineering company, we have been providing business solutions to our customers for a long time based on new technologies, which we are constantly developing and improving.

Description

1924

Kisaku Maekawa founded the company MAYEKAWA & Co.

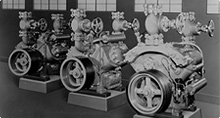

Production of vertical piston refrigeration compressors began.

1958

Developed high-speed multi cylinder compound type two-stage reciprocating compressor.

1969

Installed the first screw type refrigeration compressor for large refrigeration mother ship of 10,000 tons in capacity.

1970

Started production of compressors in Moriya Plant, Ibaraki pref. Japan.

1971

Established subsidiary company, N.V.MYCOM EUROPE S.A. in Brussels, Belgium (with annexed package plant).

1984

Established subsidiary company, MAYEKAWA AUSTRALIA PTY. LTD. in Sydney, Australia.

Established subsidiary company, MYCOM PERU S.A.C. in Lima, Peru.

1989

Developed second-generation high-speed multi cylinder reciprocating compressor ‘WA and WB Series’

1990

Developed the screw compressor 160V-320V series.

In addition to compressors, the technological innovation advanced in some industrial fields, such as development of freezers with unique features or automated meat processing machines.

1994

Delivered the first automated chicken whole leg deboning machine ‘TORIDAS’.

1996

Started selling the impinging jet system new tunnel freezer ‘Thermo-Jack Freezer’.

1998

Ammonia refrigeration systems were supplied to all ice palaces, as well as bobsleigh and luge tracks for the Winter Olympic Games in Nagano, Japan.

Sales of robotic machines for deboning chicken and turkey carcasses (TORIDAS and TAKIDAS series) have begun on the European market.

2001

Compound 2-stage helium compressors were supplied to the CERN research center in France/Switzerland (the world’s largest helium compressor system).

2002

Delivered the first automated turkey whole leg deboning machine ‘TAKIDAS’.

2003

Developed reciprocating compressor for CO2 (carbon dioxide) heat pump.

2004

Delivered the first CO2 heat pump for hot water supply.

Upgraded the automated chicken whole leg deboning machine ‘TORIDAS’.

2008

Developed semi-hermetic screw compressor and its IPM motor for ammonia refrigerant.

Delivered the first NH3/CO2 cooling system ‘NewTon’.

Developed expander integrated turbo compressor.

Developed energy saving type reciprocating compressor ‘M series’.

Developed Automatic Variable Vi Mechanism integrated type screw compressor ‘J series’.

2009

A robotic line for deboning pork hams “HAMDAS-R” was delivered to the Netherlands (the first project of its kind in Europe).

Delivered the first CO2 heat pump for hot air supply ‘Ecosirocco’.

2011

Delivered the first automated pork ham deboning machine ‘HAMDAS-RX’.

2014

Delivered the first automated pork shoulder deboning machine ‘WANDAS-RX’.

Delivered the first automated chicken wing drumettes deboning machine ‘WINGDAS’.

2015

Launched “DAS”, a new deboning machine brand.

Delivered the first automated front half deboning machine ‘YIELDAS3000’.

2016

The Mayekawa MYCOM company, based on the ALFA Contracting Ukraine company, has opened a representative office in Ukraine.

Launched “CHORUS”, a new freezer brand.

2018

Established subsidiary office, MAYEKAWA UKRAINE LLC, in Kiev, Ukraine.

2019

The first automated deboning machine for whole chicken legs “LEGDAS” was delivered, which has triple the capacity of “TORIDAS”.

2023

Delivered the first cell system for pork cut meat processing ‘CELLDAS SYSTEM’.