Goals and objectives

Environmental sustainability is a priority in MAYEKAWA’s business activities.

Description

Goals and objectives

We have been developing technologies using natural refrigerants and energy saving solutions for a long time.

The use of natural refrigerants and thermal energy developments that require less energy are aimed at supporting sustainable development, eliminating ozone depletion, and stopping global warming.

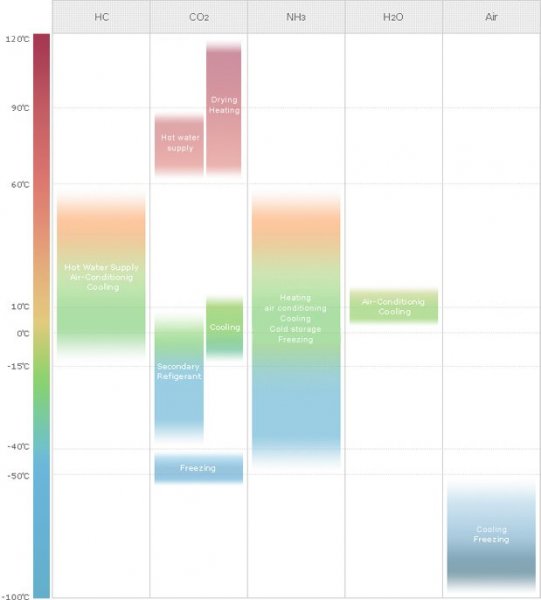

Natural refrigerants have a lower GWP (Global Warming Potential) than HFCs and zero ozone depletion potential, making them environmentally friendly refrigerants. Mayekawa designs and manufactures a wide range of equipment suitable for operating over a wide temperature range for heating and cooling applications. We call this approach NATURAL FIVE: five natural refrigerants: ammonia (NH3), carbon dioxide (CO2), water (H >2O), hydrocarbon (HC) and air. These natural refrigerants are used in heating, drying, hot water, air conditioning, refrigeration and refrigeration systems over a wide temperature range from -100ºC to 200ºC.

We have in-depth knowledge of heat pump technology powered by renewable energy sources, including water, air and geothermal heat as an energy source.

By achieving maximum heat pump performance, we can benefit from renewable and waste energy sources while conserving natural resources.

Ammonia NH3

Ammonia is the most popular and traditional natural refrigerant.

MAYEKAWA develops systems that use minimal amounts of ammonia and are safe to use.

For example, MAYEKAWA supplies electrically driven semi-hermetic compressors.

We also offer NH3 / CO2 brine cooling systems because they can reduce the overall volume of ammonia consumed.

This hybrid NH3/CO2 technology is used in our highly efficient systems across a wide temperature range: refrigeration systems for cold stores, rollers and compressors for freezers.

Carbon dioxide CO2

CO2 as a refrigerant has an extremely low environmental impact. It has a global warming potential (GWP) of 1/3920th the GWP of HFCs and CFC replacements. CO2 is much safer: it is non-toxic, non-flammable and has high cooling power. CO2 refrigerant is listed as a low environmental impact refrigerant in the Montreal Protocol (MOP21), approved in 2009.

MAYEKAWA offers safe refrigeration systems in which ammonia-fueled refrigeration units cool CO2 as a secondary refrigerant. However, NH3 refrigerant is not present in the internal areas of cold storage warehouses and air conditioning systems.

We use CO2 for more than just refrigeration and freezing. We also offer heat pump systems for heating, hot water and drying with our CO2 MYCOM compressors.

Air

MAYEKAWA has developed a freezer that uses the air we breathe as a refrigerant. Air has no impact on the environment, it is an absolute natural refrigerant. Ideal for extremely low temperatures (-50℃ – -100℃), this system can reduce energy consumption and CO2 emissions by up to 50%. It can be used for general purposes including use in ultra-low temperature frozen tuna warehouses and freeze drying plants, as well as other applications such as municipal waste recycling (freezing and crushing), semiconductor manufacturing, medical and pharmaceutical industries and physical and chemical processes.

Water H2O

When water evaporates in a vacuum, it cools because… its latent heat escapes through evaporation.

Adsorption chillers can continuously produce chilled water ranging from 3℃ to 25℃ using waste water or other water sources ranging from 60℃ to 100℃. All this occurs without the use of mechanical compression, as is the case with standard vapor compression refrigeration systems. As a result, adsorption chillers provide industrial refrigeration and air conditioning at very low energy consumption levels.

MAYEKAWA adsorption chillers can be used to cool water for air conditioning using solar energy as a heat source or to produce chilled water from waste water to reduce energy consumption.

HC hydrocarbon

Hydrocarbon refrigerants have zero GWP, ozone depletion potential less than 3 and are non-toxic.

The operating pressure of HC is lower than that of carbon dioxide (CO2), allowing the use of standard compressors, and while hydrocarbons are highly flammable, projects and MAYEKAWA safety equipment reduce the risks to the levels of other refrigerants.

MAYEKAWA has also developed HC heat pumps for air conditioning and hot water applications for district heating and cooling systems where the use of natural refrigerants is still limited.

This system minimizes the risk of refrigerant leakage by using a compressor with a semi-hermetic motor. Built-in safety devices maintain refrigerant concentrations below LFL/LEL*. The system is designed to operate with a minimum amount of refrigerant to ensure a high level of safety even in the unlikely event of a refrigerant leak.

The hydrocarbon unit can be used for heating and hot water up to 65℃, water cooling systems and ice storage systems.

* LEL: Lower Explosive Limit / LFL: Lower Flammable Limit